Climbing the Learning Curve with Your New Fusion3 3D Printer

Chances are, if you’re buying a 3D printer for your business, you have a specific challenge, or a specific project, in mind that you want to address using this technology. And 3D printing is a very powerful, flexible problem-solving tool if it’s used correctly.

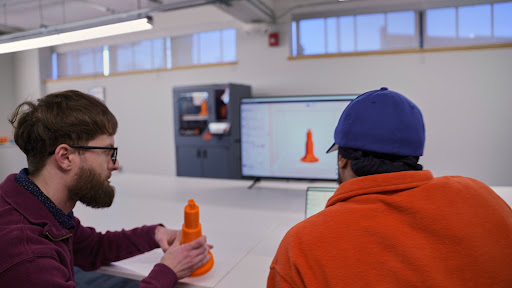

One of the biggest sources of headaches for our new customers we see is when they try to jump into a large, complex project with their new Fusion3 printer before they’re fully familiar with the equipment and how to use it. This creates a lot of frustration, wasted material, and blown up schedules. Remember: Fusion3 3D printers are complex machine tools, not appliances. Our products are much more capable than consumer-grade printers; but with that capability comes additional complexity and lower “guardrails”, so to speak.

Our goal with this article is to provide some helpful guidance on how long you should plan to allow for the users of your new Fusion3 3D printer to climb up the learning curve and be ready to tackle your big challenging projects

What Does the Learning Curve Consist of?

When we say learning curve, we mean a period of time where you’re gaining familiarity and expertise with your Fusion3 printer. You will spend some time learning the hardware and software, and some time running prints. Some of these prints will be “just for fun” or to try something out, and some of them will be attempts at a “real” part for your needs or application. There’s no better way to learn than jumping in and experimenting.

You should plan for this time to be non-productive. That is, don’t assume any of your prints will be useful for anything, even if you are printing the parts your project requires. This gives you the freedom to learn and experiment – and have prints fail – without blowing up your project’s schedule.

As you gain experience and an understanding of the system, your failure rates will drop and you’ll start to turn out prints that are useful for your end application. Depending on a number of factors, some of which we discuss below, this could be a single-digit number of days or weeks.

The important thing is to avoid putting yourself under artificial time pressure right out of the gate. Just like you wouldn’t expect a teenager learning to drive to be competitive in a race, don’t do the same thing to yourself!

Level of 3D Printing Experience

The most important factor is how experienced you are with 3D printing in general. People who are totally new to the technology should plan for a longer learning period than folks who have a background with industrial machines or consumer printers. And if you have previously had a Fusion3 printer, your learning curve will be even shorter (but still there!)

It’s important to remember that even if you are an expert with other 3D printers, do not assume Fusion3 products will work exactly the same. Please attend our training classes and read our documentation, and take your time! The people we see who get in the most trouble come from a consumer/hobbyist 3D printer background, and try to apply exactly the same workflows to our products. They don’t contact us for help for weeks, by which point they are utterly frustrated and very behind on their projects. It never hurts to reach out to us early and often, even if you just have questions about something.

Materials You Intend to Use

In general higher-performance materials are fussier to work with and require a greater degree of skill and knowledge in order to get good results. If your project requires a material like polycarbonate, nylon or fiber-filled varieties of materials, plan for additional time to gain familiarity with these materials.

In many cases, you can run trial prints in an easier-to-use material such as ABS as a way to gain experience.

General CAD Experience & Designing for 3DP

3D printing has a few key components: understanding the hardware (the printer), understanding the materials, and understanding the software. In our decade of experience, the more familiar our customers are with 3D CAD, the faster they pick up the software side.

“Software side” is really two things:

- Understanding the slicer and how to use it. The slicer is a piece of software that generates the instructions for the printer.

- Understanding how your CAD designs interact with the slicer and the printer. And subsequently understanding how to “design for 3DP” to get the best results.

There is no shortcut here for accumulating experience printing your own designs. But familiarity with other manufacturing processes can help.

Designing for 3DP is a huge topic on its own. To keep it short, 3DP has a different set of strengths and weaknesses compared to other manufacturing technologies such as injection molding and machining. While 3DP can be used to make parts designed for other manufacturing processes, you can get better results, and performance, if you design with this technology in mind.

Number of Users

The more people you have using your 3D printer, the longer it will take to get the whole team up to speed.

- People absorb information at different rates

- Some people will get more experience than others

- More people = more opportunity for confusion. Who performed a maintenance item… Did someone change the print head out… etc

Our recommendation is you designate one or two people as “power users” who are responsible for using the printer, maintaining the printer, and setting up prints. These power users are the interface between the rest of your organization and the printer. Later this requirement can be relaxed if appropriate.

Putting it All Together

So, how long should you plan to spend with your Fusion3 printer before deploying it in your mission critical projects? It depends on a lot of factors.

AT MINIMUM: Plan for 2 weeks to familiarize yourself with your new printer and its workflows. This would be for folks who are already experts with 3D printing, have a strong CAD background, and understand how to deploy 3DP in various uses, and a small team.

AT MAXIMUM: Plan for up to 1.5 months. This would be appropriate for a large team of many users, many different applications for the technology, and a weaker CAD background.

Some other quick notes to keep in mind:

- All new Fusion3 customers, regardless of skill level, should plan to attend our weekly free training sessions. Sign up HERE.

- If you have specific materials you need for your projects, order them ahead of time. We continue to see supply chain disruptions in the filament market, and many specialized materials can be hard to find.

If you have a large project coming up and are planning to use Fusion3’s printers, please factor this learning curve time into your plans to ensure you have sufficient time to come up to speed on the technology and are ready to hit the ground running!