Fusion3 EDGE Return on Investment

THE TAKEAWAY

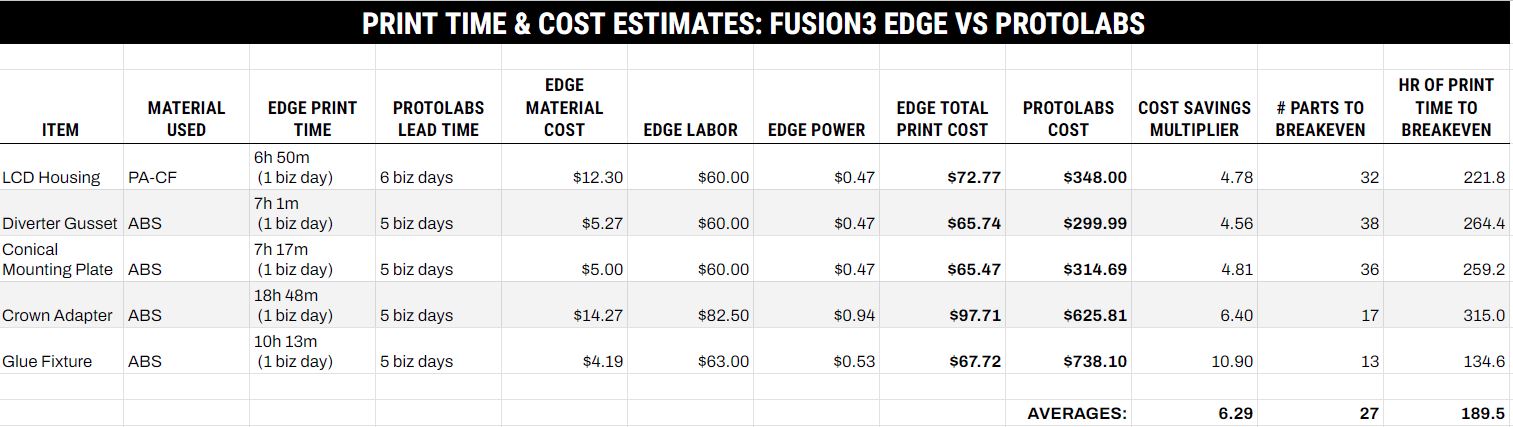

- On average, EDGE pays for itself in 190 hours of printing, or about 27 finished parts.

- This calculation is based on the comparison of in-house printing with EDGE versus outsourcing the same print jobs.

- EDGE is, on average, 6.3x cheaper per-part compared to outsourced prints.

- EDGE delivers parts 4 to 5 days earlier than outsourced prints.

Request a Quote

and learn more about how EDGE can deliver high-impact ROI for your business

Like any business tool, a Fusion3 3D printer needs to provide a positive expected value for your business:

- How is this going to save me money?

- How is this going to save me time?

- How is this going to expand my capabilities?

- How is this going to reduce IP risk?

HOW IS THIS GOING TO SAVE MONEY?

By bringing the printing process in-house, businesses can save substantially on manufacturing expenses. This makes it more affordable to experiment with new ideas and prototypes. Additionally, using the Fusion3 EDGE printer allows companies to transition from CAD designs to real-world products earlier in the design process, facilitating early testing and evaluation.

HOW IS THIS GOING TO SAVE TIME?

Outsourcing to services like Protolabs typically takes 5-6 business days, with the option to expedite at a higher cost. In contrast, Fusion3 3D printers’ rapid print time ensures that you can have parts ready within the day.

The time saved with the Fusion3 EDGE printer means your team can spend less time waiting and more time testing, iterating, and improving your products.

To put a monetary value on time savings, follow this equation:

- 4 days x cost of your team waiting for parts

- Example:

- 2 engineers who make $150k/year = $72/hour/each

- 4 days x 8 hours x 2 = $2,304 spent waiting for a Protolabs part

- This does not account for the cost of delaying the program/product by 4 days. This delay costs compounds over the development cycle.

HOW IS THIS GOING TO EXPAND MY CAPABILITIES?

- Tighter feedback loops:

- Iterative learning, where designs are constantly tested, refined, and improved, is essential for efficient product development

- In-house 3D printing will dramatically accelerate this learning loop

- Faster output also means that your employees will directly interact with the technology more frequently. This will increase their understanding of the products and increase productivity.

HOW IS THIS GOING TO REDUCE INTELLECTUAL PROPERTY (IP) RISK?

3D CAD files are valuable assets, and by outsourcing printing, businesses may expose their IP to external vendors, increasing the risk of loss or theft.

Doing 3D printing in-house will allow you to retain complete control over your IP and the entire toolchain – from design to slicing and printing. Additionally, Fusion3’s 3D printers & software are designed to work without internet connection. They are suitable for use in classified & secure compartmentalized (SCI) applications.

This level of control is particularly advantageous in industries where sharing IP outside the organization is restricted, such as military or defense. Protecting IP can prevent leaks, reduce rework costs, and safeguard against knockoffs and counterfeit products.

To put a monetary value on IP control:

-

- How much does a leak cost your organization (in money or time spent reworking)?

- How much money does your organization lose to knockoffs and counterfeit products?

- How much more could you accomplish if you could remain compliant with your IP / classified info handling requirements?

Interested in exploring EDGE's ROI for your specific application?

Request a quote to begin the conversation.