NYLON 3D PRINTERS

Fusion3 3D printers are versatile, high-speed, high-quality 3D printers that print a wide variety of nylon 3D printer filaments from many different manufacturers.

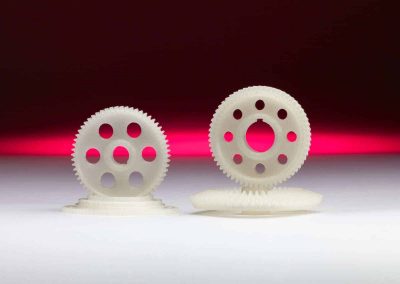

Nylon, as a material, is stiff, strong and provides outstanding bearing and wear properties. Nylon is often used to replace metal bearings and bushings, often eliminating the need for external lubrication. Other benefits of using nylon include the reduction of weight, less operating noise and decreased wear on mating parts. Some 3D printable nylons are FDA approved for food or medical use (in virgin form). Other nylons are reinforced with other materials such as carbon fiber, fiberglass, and Kevlar, which enhance the plastic’s properties in various ways (strength, rigidity, temperature resistance).

Fusion3’s various nylon 3D printers allows you to create using high-quality, high strength parts for a variety of different applications.

Front Timing Flange Nylon 3D Print with Taulman3D Nylon 645

Over 15 Different Nylon Carbon Fiber 3D Printer Filaments, Tested & Certified For Fusion3 3D Printers

We have tested and certified a wide variety of Nylon materials from leading manufacturers for use in our 3D printers. These nylons have a wide range of properties, including high wear resistance and strength, UV resistance, and FDA food-safe certification, and the addition of carbon-fiber, Kevlar, fiberglass.

Fusion3 receives requests from both customers and manufacturers to test new materials as they arrive on the market. Should they pass our rigorous testing process, we provide optimized print settings to all our customers within our F3Slic3r 3D printing software.

The New EDGE High-Performance 3D Printer

Optimized For 3D Printing Higher-Temperature Materials Including ABS

FUSION3’S 3D PRINTERS ARE DESIGNED FROM THE GROUND UP FOR SUPERIOR 3D PRINTING OF NYLON PARTS

Our Enclosed, Passively Heated Print Chambers Provide Excellent Nylon 3D Prints

Nylon Requires a Heated Chamber To Achieve Strong Layer Bonds & Strengthn

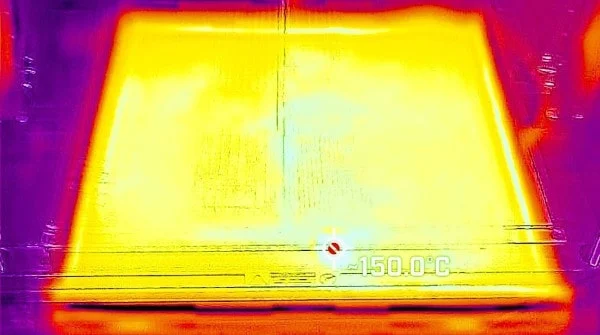

Every Fusion3 comes standard with our high-power, multi-zone heated bed. Combined with a high-temperature, high-power print head, such as the new ANVIL print head featured in our Fusion3 EDGE, and an enclosed print chamber, Fusion3’s optimized nylon 3D printers have no issue getting high-performance nylon filaments hot enough. By keeping your 3D printer warm to achieve high-strength layer bonding, you will get strong, effective, long-lasting parts.

Infrared Image of the Fusion3 EDGE’s Multizone Heated Bed

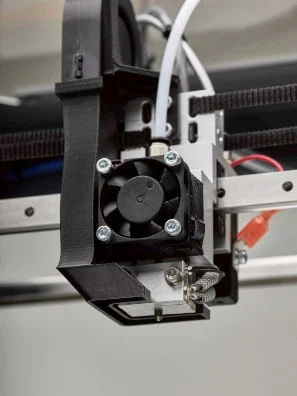

Fusion3’s High-Temperature, High-Flow Precision Print Heads

Nylon Materials Require Precise Temperature Control

Nylon is a highly capable, high-performance plastic when 3D printed.

However, if printed at too high a temperature, it will scorch and leave unsightly burn marks and blobs on your parts, also affecting part performance. All Fusion3 high-performance print heads provide, precise temperature control. Coupled with our provided optimized material profiles, you’ll have the correct settings for each of our certified materials to ensure the best performance for every print.

Fusion3’s Precision ANVIL Print Head

Fusion3 Provides Optimized Settings for Each Nylon Material To Ensure Great Results

Nylon Filament is Significantly More Expensive Than Generic Plastics

3D printing with many nylon materials can be expensive. Testing and experimenting to come up with failed prints until you dial in the right settings wastes time, material and money.

Fusion3’s material testing lab takes out all of this guesswork for our customers. We have already tested and certified over 15 different Carbon reinforced materials and have more in testing. These optimized profiles are found within our F3Slic3r 3D printing software ready for you to use.

Fusion3 Has The Expertise To Help You Streamline Your Nylon 3D printing Operations

Nylon Filament Absorbs Humidity Quickly And Requires Special Handling

Many customers will just rush out and buy large spools of filament in bulk just to obtain a reduced cost per kilogram of material. If you have experience and high confidence that you will consume the material in a short period of time, and already have the proper handling procedures in place, that may be an appropriate strategy.

However, materials like Nylon, once removed from their air sealed packaging, immediately absorb moisture from the air which will affect print quality. Fusion3’s sales & support team have experience working with customers to help them design operational processes to keep production and handling costs down, and provide, if needed additional options like dehumidification options or filament dryers for long-term storage of expensive nylon filaments.