HIGH-PERFORMANCE MATERIALS

ENGINEEERED TO DELIVER

Many Fusion3 customers seek to 3D print the same engineering-grade 3D printable plastics they use for injection molding. Other customers desire unique properties that new, innovative filaments can provide. The Fusion3 EDGE is engineered to deliver excellent performance with the widest range of materials available on the market, to best meet the needs of our customers.

HIGH-TEMPERATURE MATERIALS

High-performance thermoplastics are one of the keys to enabling 3D printers to solve more problems in your business. These engineering-grade materials can be challenging for consumer 3D printers to print, because they require higher temperatures and better control over the build environment.

EDGE delivers unparalleled performance with materials such as ABS, PC, ASA, and Nylons thanks to its ability to reach the correct temperatures for these materials

- 315C print head

- 145C bed

- Fully enclosed build chamber with controlled airflow through filter

- Optional chamber heater (max chamber temp 70C)

Our favorite high-temperature materials include:

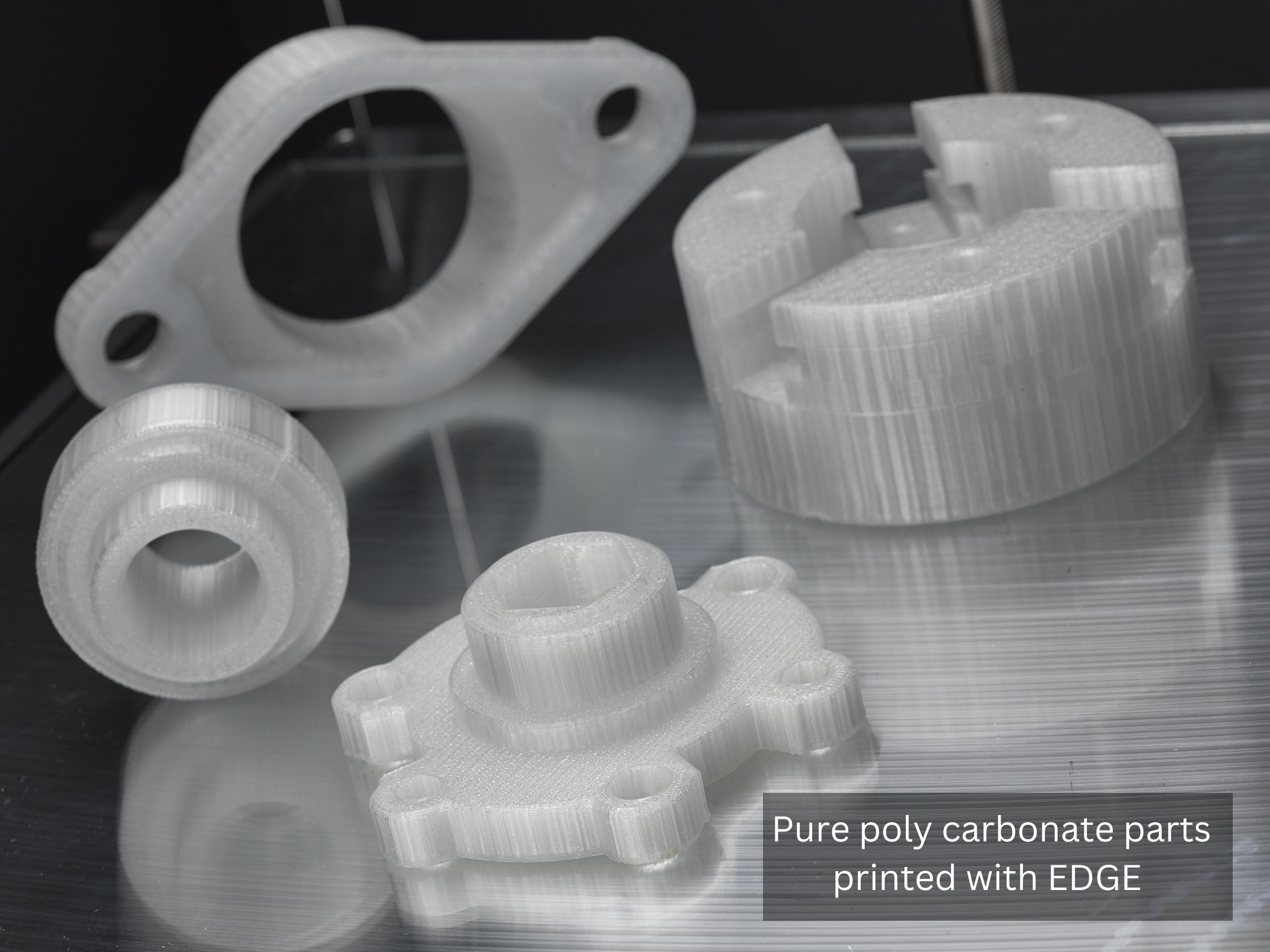

- Pure polycarbonate (Tg 140C) (“easy print” variants mixed with other plastics need not apply)

- PC-PBT (Tg 120C)

- ABS (Tg 105C)

- ASA (Tg 100C)

- And CF- & GF-filled variants of these materials

FIBER-FILLED COMPATIBILITY COMES STANDARD

Out of the box, EDGE is capable of printing carbon fiber, glass fiber, & kevlar-filled variants of all materials.

- 0.6, 0.8mm nozzle size options for more reliable printing with high fiber content

- ANVIL print head tubes are low cost, easy to replace if damaged

- ANVIL tubes are abrasive resistant

- Filament path components are hardened and/or easily replaced if worn by abrasive materials.

THE RIGHT MATERIAL FOR EVERY JOB

Years ago, Fusion3 set a new standard for 3D printers by pioneering the concept of open but curated materials. That philosophy continues to this day.

Our open materials philosophy means:

- You don’t need to buy filament from Fusion3

- The lowest possible cost for you

- Maximum material options

- Settings for each material developed by Fusion3 for out-of-the-box compatibility and trouble-free printing

- Maximum options = you can pick the right material for your specific application.

EVERY TYPE OF 3D PRINTABLE PLASTIC

Fusion3 3D Printers can print filament from all major families of 3D printable plastic, including standard and hybrid formulations of these most utilized 3D printer materials:

- ABS

- ASA

- Carbon-Fiber Reinforced

- Co-Polyesters

- Decorative (including Wood and Stone filled)

- Fiberglass Reinforced

- Flexibles (including TPU & TPE)

- HIPS

- Kevlar Reinforced

- Metal (316l Stainless)*

- Nylon

- PET / PETG

- PLA

- Polycarbonate

- Polypropylene*

- and MORE…

TESTED & CERTIFIED TO ENSURE COMPATIBILITY AND PERFORMANCE

Purchase Directly From Suppliers

Other 3D printer manufacturers require you to only purchase their limited selection of branded material at inflated prices or encourage you to buy material anywhere, but leave you to figure out the settings to make those materials work, a difficult process for a 3D printing expert, much less someone with a job to do.

We encourage customers to purchase materials on the open market, encouraging competition in price, quality, and innovation. We only ask that you either use what is already on our Certified Materials List or have us test new filaments prior to use.

Suppliers who have had 1 or more types of filament certified for use with Fusion3 3D printers

RIGOROUS TESTING PROCESS

Fusion3 subjects new 3D printer materials to a rigorous testing process. First, we measure multiple samples of the material to ensure consistency of extrusion, as too much variation can have detrimental impacts on the performance of your high-performance Fusion3 3D printer. Then we engage in a series of different tests to ensure the quality of material and its suitability for 3D printing with the Fusion3 hardware. Should the material pass those tests, we then create the different material settings (“profiles”) for each of our 3D printers at different performance levels.

CUSTOMER REQUESTS

We encourage our customers to request the testing of new, quality materials for 3D printing. Requests range from evaluating a new, unique material or formulation for use in their industry or application, to the certification of a quality generic filament sold by a familiar or in-region supplier.

FREQUENT UPDATES

Fusion3 seeks out new 3D printer materials and printable plastics to test and frequently publish updates to our Certified Materials List and optimized print settings (profiles) which we then push automatically to users online within our F3Slic3r 3D printing (slicing) software.