MANUFACTURER OF LARGE 3D PRINTERS /

ENCLOSED 3D PRINTERS

FFF (Fused Filament Fabrication) is a fantastic technology but is also slow. An FFF 3D printer puts plastic down in a small bead, one layer at a time. This speed issue becomes magnified as part size increases.

During sales calls with customers, we often remark:

Plenty of slow 3D printers on the market can print small items with decent to very good quality using low-temperature plastics such as PLA and PETG.

What is difficult is to print large or many parts using high-temperature/engineering-grade plastics at good to excellent quality on a repeatable basis. A company gets even higher marks if their 3D printer can do these at faster speeds at quality (the prints do not take weeks at a time).

Let’s describe some of Fusion3’s advantages in 3d printing large parts or many parts at one time.

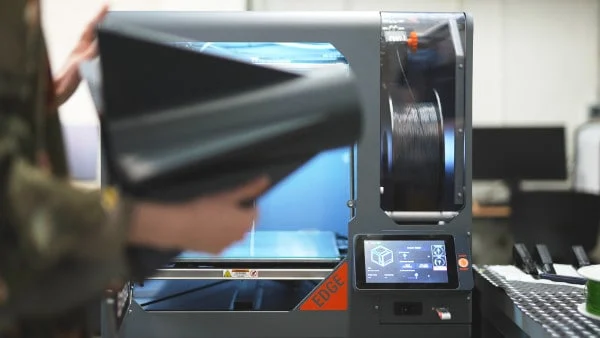

Fusion3 EDGE: Enclosed 14.5″ x 14.5″ x 13.5″ Large 3D printer

Very Large 3D Print Build Volume

Fusion3 has always been known for fast 3D printers with large build volumes.

Our first 3D printer, the F306, had a 12 “x 12″ x 12″ build area. This grew to 14″ x 14″ x 12.5” with our F400 and F410.

Our latest 3D printer, EDGE (shown) has the largest heated, enclosed build area we’ve ever produced. EDGE has a total size of 14.5″ x 14.5″ x 13.5″ (2842 cu in or almost 48,000 cu cm).

Still, for producing many parts or student assignments, the entire 14.5″ x 14.5″ aluminum tool plate allows for many items to be placed on the bed and printed using the same settings.

Fusion3 does not sell filament.

We encourage customers to purchase materials on the open market, encouraging competition in price, quality, and innovation. We only ask that you either use what is already on our Certified Materials List or have us test new filaments prior to use.

Interchangeable Print Heads / Print Tubes

Every Fusion3 EDGE 3D printer ships with a print head with our standard .4MM nozzle. This is the perfect balance of print speed and print quality.

EDGE and its ANVIL print head uses removable/replaceable surgical steel print tubes which resist wear from abrasive, infused materials (such as carbon fiber or metals). Both types, unlike brass nozzles, are the perfect choice for large format 3D printing.

You might see a smaller nozzle available, especially by hobby component providers. However, our testing has shown that a nozzle any lower than .4MM will have too slow a flow rate to be productive and have too high a probability for print jams.

Depending on your print speed and print quality requirements, we offer larger print heads/print tubes for our 3D printers, which allow you to increase the flow rate and decrease print time for large 3D prints that would otherwise take much longer with a smaller print nozzle.

.4MM

.6MM

32-40% Reduction in Print Time

.8MM

44-58% Reduction in Print Time

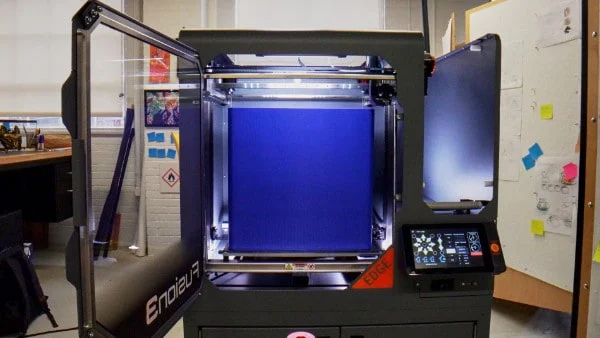

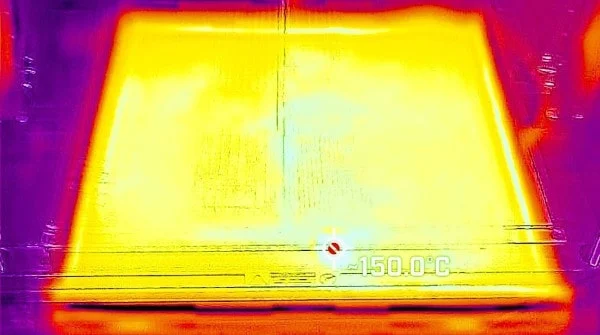

Large, Passively Heated Enclosure

Fusion3’s enclosed 3D Printers provide a stable, high-temperature environment for printing high-strength, engineering-grade 3D printing materials.

Our EDGE 3D printer features a large multi-zone heated bed which offers the right consistent temperature for proper bed and layer adhesion for all 3D printing materials.

Depending on the material you are printing, the interior temperature will vary between 30*C and up to an astounding 70*C.

Each ensures excellent print results for high-temperature, engineering-grade materials, including polycarbonate, ABS, and nylon.

FREQUENTLY ASKED QUESTIONS:

LARGE 3D PRINTERS

What is a good standard for a large 3D printing area?

A good standard for a large format 3D printer is 300mm x 300mm x 300mm and upward. The F410 has a max build size of 355 x 355 x 315mm.