F410 3D PRINTER (Offered between 2018 & 2022)

The F410 was a significant update to the F400 to improve upon its performance and create even more use cases for the 3D printing of large parts, which continuing the use of our core architecture based our the ‘F-Series motion control system’.

The F410 enjoyed improvements to the extruder with the addition of filament detection and performance, a new conductive bed leveling system, and higher flow print heads that offered .4MM, .6MM and .8MM print options for users.

The F410 is replaced for 2022 by the new EDGE 3D printer which shares the same core architecture but has been re-imagined from the ground up with new components and upgrades to maintain Fusion3’s emphasis on speed & expertise in printing engineering-grade materials, while improving the durability and reliability of the platform and also improving the ease of use of operation and maintenance. All the while seeing dramatic improvements in print quality that have EDGE printing 20% to 40% faster than competitors with similar or better print quality at standard settings.

Note: As with all Fusion3 3D printers, our F410 customers receive phone & email support for the life of their 3D printer and while the F410 is no longer for sale, we expect to be able to provide replacement parts for another 4-6 years as we have done with our previous products.

The Fast, Affordable, Professional 3D Printer

Within every budget for business & education, only $4,999

Heavy Duty Rolling Cart Sold Separately

AFFORDABLE, HIGH-PERFORMANCE 3D PRINTING

Combination of precision, speed and reliability, utilizing Fusion3’s unique technology and focus on throughput.

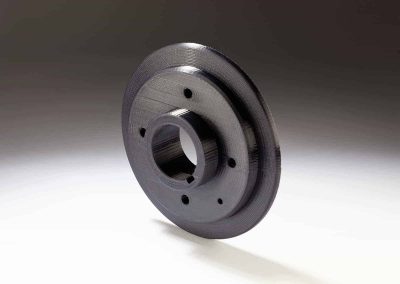

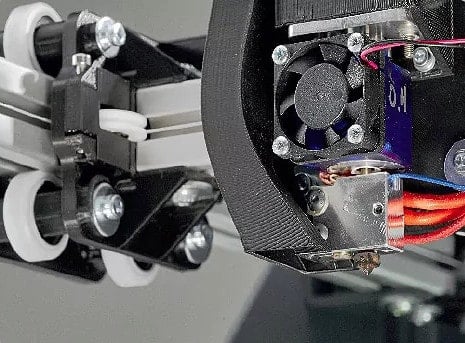

- Redesigned 2.0 Extruder with Filament Monitoring, Filament Cleaning and improved grip and enhanced performance with all materials.

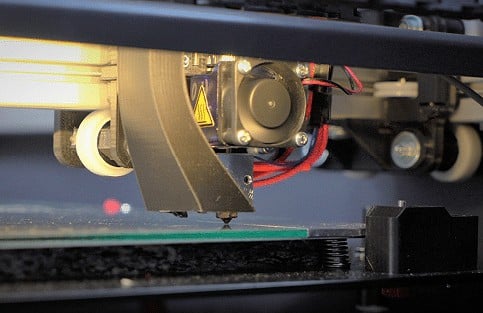

- ‘F-Series’ platform combines high stiffness, low ® moving mass, and a high-performance Kevlar cable system, enabling the F410 to print faster and more accurately than other 3D printers in its class.

- Rigid metal enclosure provides a stable platform, eliminating vibration and ensuring fast, quality prints.

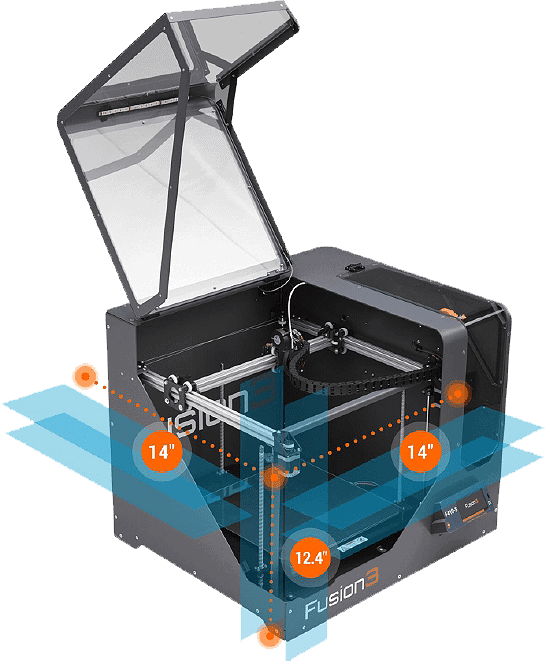

LARGE, ENCLOSED 3D PRINTER

The F410 3D printer’s enclosed print chamber and interchangeable print heads enable you to produce large parts, using high-temperature materials.

- With a maximum build volume of 1.38 cubic feet (max build size of 355 x 355 x 315mm), the F410’s large print bed enables fabrication of large parts, or large numbers of smaller parts, in one print job.

- Choice of three (3) interchangeable print heads (.4MM included, .6MM and .8MM purchased separately) to achieve the best balance of print speed and print quality. All are equipped with hardened steel nozzles which resist wear from abrasive, infused materials (including carbon fiber).

- The F410 3D printer large heated bed ensures proper bed adhesion for all 3D printing materials. Together, F410’s enclosed print area and multi-zone heated bed provide a stable 45*C environment, ensuring excellent print results for high-temperature, engineering-grade materials including Polycarbonate, ABS and Nylon.

WIDEST VARIETY OF 3D PRINTER MATERIALS

Fusion3’s testing & certification process ensures our customers can successfully print the widest variety of materials for 3D printing ‘out of the box’.

Sample Parts 3D Printed on the F410 in a Variety of Different 3D Printer Materials

- We encourage customers to purchase materials on the open market, encouraging competition in price, quality, and innovation. We only ask that you either use what is already on our Certified Materials List or have us test new filaments prior to use.

- Fusion3 subjects new 3D printer materials to a rigorous testing process. Should the material pass those tests, we then create the different material settings (“profiles”) for each of our 3D printers at different performance levels.

- We encourage our customers to request the testing of new, quality materials for 3D printing.

- Fusion3 seeks out new 3D printer materials and printable plastics to test and frequently publish updates to our ‘Certified Materials List’ and optimized print settings (profiles) which we then push automatically to users online within our REACTOR 3D printing (slicing) software.

QUIET AND SAFE FOR WORKPLACE & SCHOOLS

Fusion3 has always recognized the safety and comfort aspects of 3D printed as a key factor in the adoption of 3D printing.

- The F410’s door, with large windows, protects users from contact with high-temperature surfaces and sensitive electronics while providing an engaging visual experience.

- The F410 is the quietest 3D printer we’ve ever built, reducing distraction to co-workers and students. At only 36db, the F410 3D printer is quieter than an everyday office and classroom, and only detected in a completely silent environment.

- Our optional filter assembly connects to the F410’s exhaust port and houses two different 3D printer air filters for use in locations lacking adequate ventilation: a carbon filter to reduce unpleasant odors and a HEPA filter which captures some amount of potentially hazardous emissions.

- Our rolling cart helps you save valuable desk space and makes it easy to move your 3D printer. The cart mirrors the design of the F410 with all-metal, heavy-duty construction, a large storage area and pass through ports for your power and network cables.

Learn more about how Fusion3 addresses the safety & comfort aspects of 3D printing…

TAKING THE GUESSWORK OUT OF 3D PRINTING

The F410 takes some of the guesswork out of producing excellent results by including features that make 3D printing easier.

Automatic, Conductive Bed Leveling

A level print bed is key to printing well. The F410’s bed level compensation technology checks and adjusts the bed height before every print. Our conductive system is elegantly simple, using the print head instead of an external sensor and ensures excellent, repeatable results.

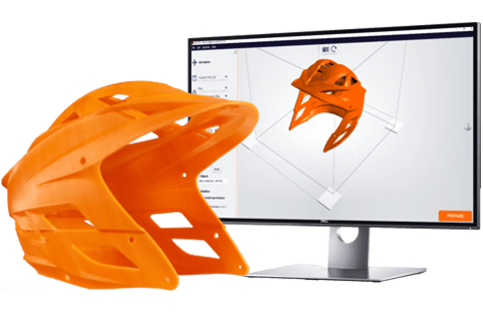

Powerful Slicing Software

Every F410 includes a copy of Fusion3’s REACTOR 3D Printing Software. A dedicated, commercial software experience (not open-source) that harnesses the company’s 3D printers’ capabilities and features.

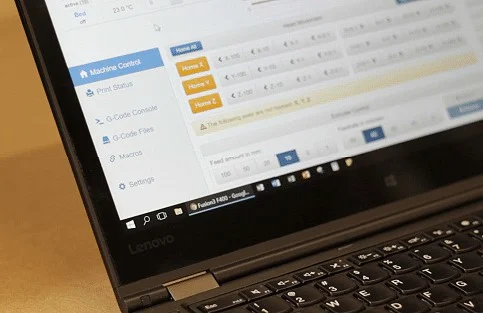

Remotely Manage Over Your Network

You can securely control your Fusion3 3D printer, remotely over your network through the F410’s built-in Ethernet connection or add-on WiFi adapter. You have complete control of your printer including uploading and managing files, monitoring print progress, and start/pause/stop of the current print job.

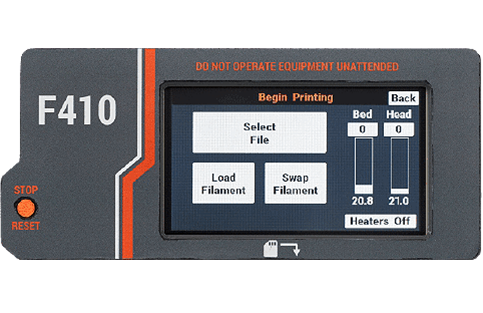

Intuitive Touch Screen Controls

The user interface on the F410’s 4.7″ full-color touchscreen makes printing and maintaining your F410 simple and easy while still giving you access to advanced controls when you need them.