LARGE, FAST, HIGH-QUALITY PC 3D PRINTERS

Polycarbonate (PC) is unmatched in terms of impact toughness, strength, and temperature resistance. Because of these traits, it’s an excellent choice for demanding applications such as automotive / under-hood components, aerospace, or other “real world” applications for 3D printed parts. However, high performance comes with a downside: PC is very difficult-to-impossible to print well on hobbyist 3D printers. It requires very high temperatures and excellent control over the build environment in order to print well.

Fusion3 products are engineered to deliver excellent, consistent performance with high performance, high temperature materials, including polycarbonate.

- High temperature heated bed (145C max)

- High temperature print head (315C max)

- Fully enclosed, passively heated chamber (with optional chamber heater accessory).

- Chamber temperature readout

- ¼” aluminum toolplate for even heat distribution

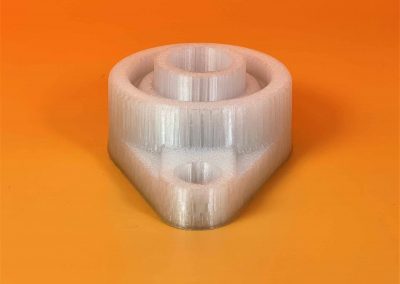

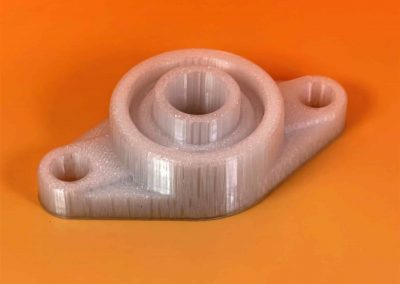

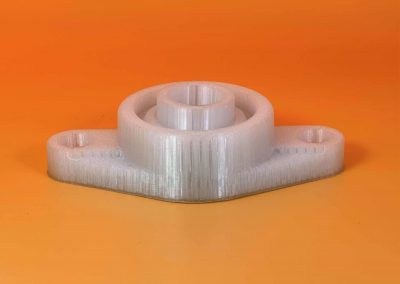

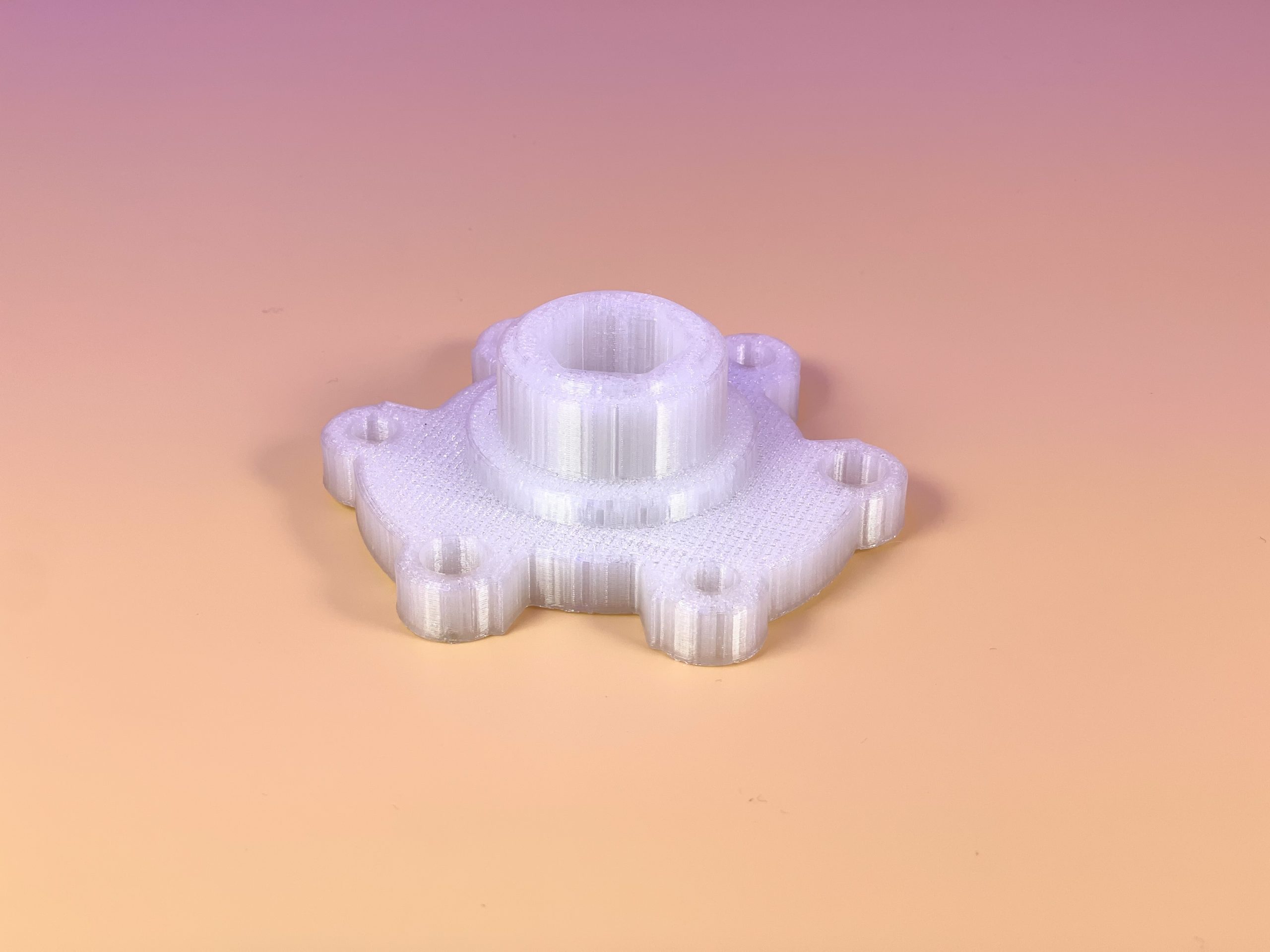

PC 3D printed Hex Hub

There are hundreds of PC 3D printer filaments on the market, many from overseas/low-cost markets. However, it is worth spending a few more dollars per kilogram for filament from a high-quality domestic supplier who focuses on precision and consistency of extrusion.

12+ Certified Generic and Specialty Suppliers of Polycarbonate Filament

We have tested and certified a wide variety of PC materials from leading manufacturers for use in our 3D printers.

Fusion3 receives requests from both customers and manufacturers to test new materials as they arrive on the market. Should they pass our rigorous testing process, we provide optimized print settings to all our customers within our F3Slic3r 3D printing software.

The New EDGE High-Performance 3D Printer

Optimized For 3D Printing Higher-Temperature Materials Including PC

FUSION3’S 3D PRINTERS ARE EXPRESSLY DESIGNED TO PRINT HIGHER-STRENGTH / HIGHER TEMPERATURE MATERIALS LIKE ABS FOR EXCEPTIONAL RESULTS

Enclosed, Passively Heated Print Chamber For Optimal Results

PC Parts Must Stay Warm For Proper Layer Adhesion

Every Fusion3 3D printer’s enclosure does two important things to ensure great layer adhesion for your 3D printed PC parts. First, the enclosure passively retains heat given off by the heated print bed and the print head, raising the ambient temperature of the build chamber and further reducing thermal stress. Second, The enclosure eliminates the influence of air drafts, like downdrafts from air conditioning which could rapidly cool the part.

Infrared Image of the Fusion3 EDGE’s Multizone Heated Bed

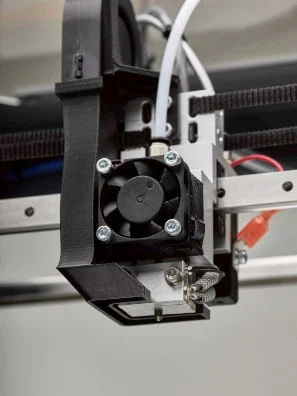

Precision Print Heads For High-Temperature, High-Flow 3D Printing

Successful PC 3D Prints Require Your Print Head To Melt Quickly And Keep Up

Fusion3’s focus on speed and print quality has required us to use high-flow, high temperature print heads that allow for quick heating of material and sustained, high temperatures to maintain a high rate of material flow. Our Fusion3 EDGE maintains this tradition, using our new ANVIL print head. With its surgical steel print tubes, and higher performance PT1000 temperature sensor and heater cartridges, EDGE is able to heat quickly and maintain the fastest flow rates of any 3D printer Fusion3 has ever built, maintaining consistent high heat, ensuring rapid extrusion and strong bonds between the layers.

Fusion3’s Precision ANVIL Print Head

High Power, Multi-Zone Bed Heaters

PC Parts Require a Hot Print Bed To Avoid Warping

Fusion3’s 3D printers have always used high-power, multi-zone print beds. This technology breaks the print surface into multiple, discrete zones with different power densities, keeping the entire Fusion3 3D printer’s surface at the same temperature. This helps prevent undesirable cooling of the 3D printed PC part and warp for properly designed parts.