AUTOMATIC BED LEVELING 3D PRINTER

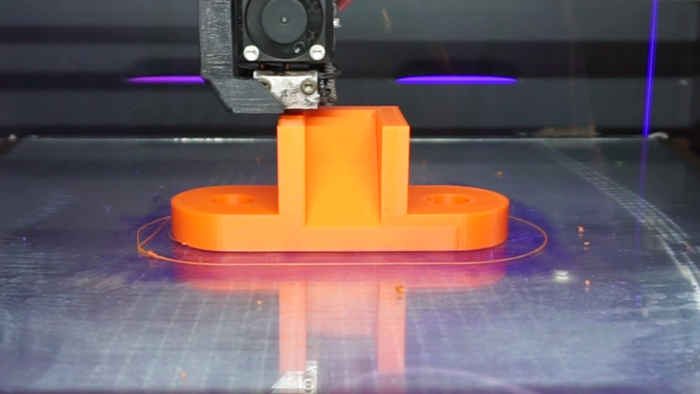

A great first layer is the the foundation of every successful 3D print.

This is even more important when making parts with higher temperature, engineering-grade materials that are susceptible to warping, including ABS, Nylon and Polycarbonate.

When Fusion3’s R&D department worked on the initial specifications for EDGE, the incorporated both our vision and experience in building 3D printers, with our customer feedback to design a great bed leveling system that will deliver a near-perfect first layer every time, without ‘over-engineering’ the system, which adds unnecessary cost and complexity.

The result is the bed leveling system in EDGE that combines our ANVIL print head, a proprietary ultra-lightweight bed probe, a 1/4″ aluminum print bed, and a mesh leveling system that together provide a near-perfect first layer every print.

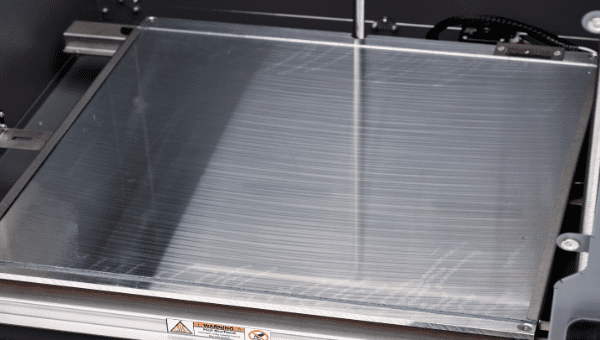

1) ALUMINUM TOOL PLATE PROVIDES A SOLID FOUNDATION

Every Fusion3 EDGE comes standard with a 1/4″ Aluminum tool plate with glass print surface (or optional 1/4″ magnetic aluminum tool plate with glass and optional magnetic surfaces such as PEI, garolite, kapton and others) which provides a nearly perfectly flat plane and makes leveling the print bed much easier than other systems.

1/4″ Aluminum Tool Plate and Glass Print Surface

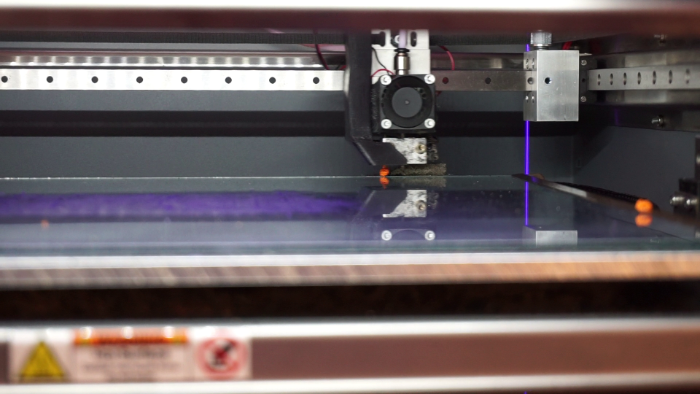

2) EDGE CALCULATES “Z-OFFSET” AUTOMATICALLY

The EDGE 3D printer uses a conductive system to measure and calibrate the ‘Z-Offset’ of the print head.

However, before it can run an electrical current through the print head and ground it against a location used as a reference point, EDGE will run the print head through a cleaning pad located at the rear of the print bed to remove any debris from the print tube which might interfere with a proper electrical connection.

Fusion3 EDGE Print Head Cleaning Itself Before Calculating its ‘Z-Offset’

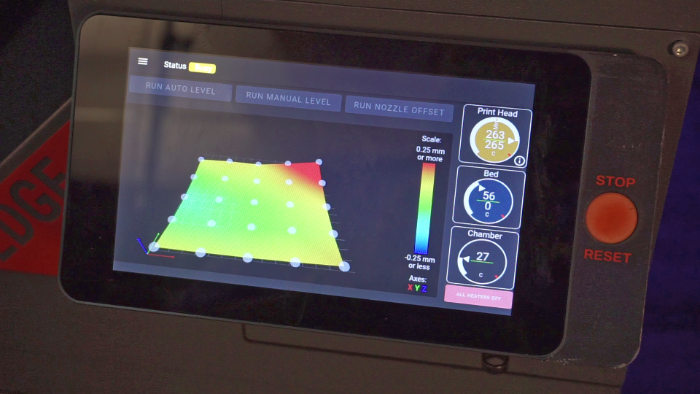

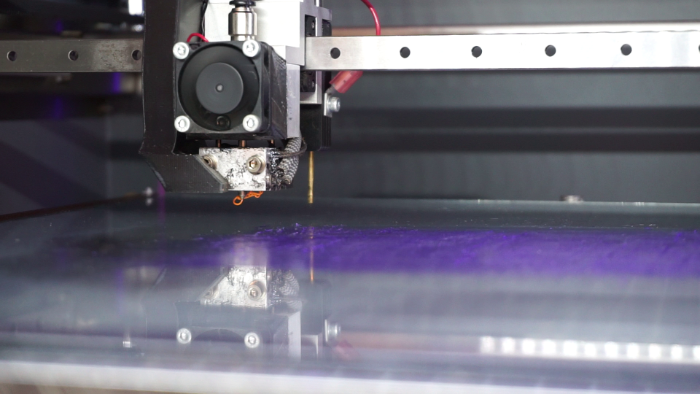

3) LIGHTWEIGHT TOUCH PROBE PROVIDES HIGHLY DETAILED MAP

The EDGE lightweight touch probe then probes the print surface at 25 points, creating a highly detailed map of the print surface.

EDGE Mesh Leveling System, On-Screen Results After Measurements

Ultra-Light Bed Leveling Touch Probe

4) MESH LEVELING SYSTEM COMPENSATES DURING PRINT AS NEEDED

If the print bed is found to be out of level in any sector, the mesh leveling system adjusts the Z axis during the print, to ensure a successful print and the best part quality.