Improved Materials List for Fusion3 Products

At Fusion3, we pride ourselves on offering the highest quality products and services to our customers. We’re excited to announce an update to our approved materials list. We’ve updated the list, added some new materials, and added some new information to support our multiple product platforms.

You can click here to view our updated materials list.

Materials List Update

We know the importance of having the correct information available at the right time. As Fusion3 continues to develop our services and improve our products, we focus on providing the most updated information to our customers.

We’ve gone through our existing materials list and removed materials that are no longer available due to supply chain issues or stopped production. Materials we think are only temporarily unavailable we have left on the list for preorder possibilities. We’ve also de-certified a handful of materials from a supplier that no longer meets Fusion3’s quality standards.

If you have questions about this decision or would like further details regarding our updated material list, please contact the Fusion3 support team.

New Materials Available

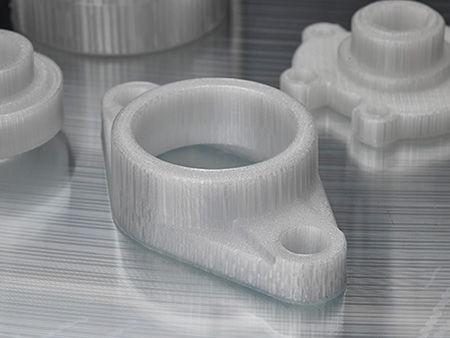

Not only did we remove outdated information from our materials list, but also we improved it with new options. We’re excited to announce some major additions to our approved materials list including:

BASF Ultrafuse 316L

If you have an application:

- With complex geometry not suited to machining or subtractive processes

- Where MIM is not feasible due to low volume, geometry, cost, etc.

- You require the strength or temperature performance of metal

Printing with BASF Ultrafuse 316L may be a good option for you to consider.

- Significant non-isotropic shrinkage that must be accounted for at the design/print stage (scaling factors are 119.82% for X and Y, 126.10% for Z)

- Strict requirements on print surfaces and coatings to prevent contamination

- Stricter than normal part shape, size requirements

- Your “green” (printed but not sintered) part must be sent away for post-processing, unless you have the necessary equipment in house

- This material is EDGE-only. We have a profile available for F410, but it’s not officially supported on this platform

For more information see:

Polypropylene

Polypropylene is commonly used in injection molded parts where good flexibility and toughness are needed. Oftentimes it’s used as a lower-cost alternative to a fiber-filled nylon.

Polypropylene is not an easy material to print and is for advanced users only. Before working with polypropylene, consider the following:

- Pronounced tendency to warp

- Proper surface prep is key. Improper prep will lead to insufficient adhesion, or too much adhesion and your part will be permanently bonded to the print surface

- Your EDGE must have the optional magnetic bed plate

- Requires a stainless steel print plate, polypropylene sheet laminated to the plate, and Magigoo PP as a release agent

Right now, we have one PP filament certified with more on the way. This is not a material category with a lot of options, so if you are interested in printing polypropylene and encounter a material you’d like to use, reach out to our support team and we can assist you.

Additional Polycarbonate Filaments

- 3DXMax PC (unfilled/normal PC)

- CarbonX CF-PC (carbon fiber filled)

- ezPC (“easy to print” has modifiers mixed in)

For parts that require high strength and high temperature resistance, one of our favorite materials is CF – PC. Not only do your parts look great, but also the carbon fiber (CF) fill helps resist warping forces, so even larger parts are possible.

For EDGE, there’s not much need for ezPC since this platform prints normal polycarbonate so well. If you have large parts to print, F400/F410 may be the better option.

An additional change for all polycarbonate materials is we now list Magigoo PC as an approved alternate bed coating. If you experience adhesion issues with gluestick, or want something with more grip for your larger PC prints, Magigoo PC may be a good option for you.

Materials List Reorganization

With the addition of our new EDGE platform, our material landscape has become more complex. Our updated materials list has some additional information to help you print successfully including:

Print Surface: What surface should be used with this material? Most of our materials use glass, but some new materials for EDGE require special removable/interchangeable print surfaces.

PLEASE NOTE: For EDGE, we’re only listing our “officially recommended” print surface for each material. Many materials are compatible with other surfaces (such as the PEI flexplates) but in the interest of keeping the list legible, we didn’t include this info. Feel free to experiment and see what works for you!

Bed Prep: How should the print surface be prepared? Most materials use gluestick (1, 2, or 3 layers), but for some materials there are acceptable alternatives. Other materials may use a removable surface which has its own rules.

Expertise Required: Previous material lists have included this and we haven’t changed anything here. This info is our attempt to communicate how difficult it is to work with a certain material.

Printer Compatibility: What product platforms is this material officially supported on?

ONE FINAL NOTE: There are two versions of the material list. The “web” version is what’s on our website and has all this info. To increase legibility in the printed version, we’ve omitted some of these columns.

Transparency and Customer Service Are Our Priorities

Our goal is to continue to meet our customers’ changing needs with the most current products and services available. If you have new materials or suppliers you’d like us to add to our approved materials list, please reach out to our support team.