Materials List Update: New Materials

We’re excited to announce another update to our Certified Materials List. This update includes some new high-performance materials from our favorite suppliers, as well as a major update to the list structure itself.

Update to List Structure

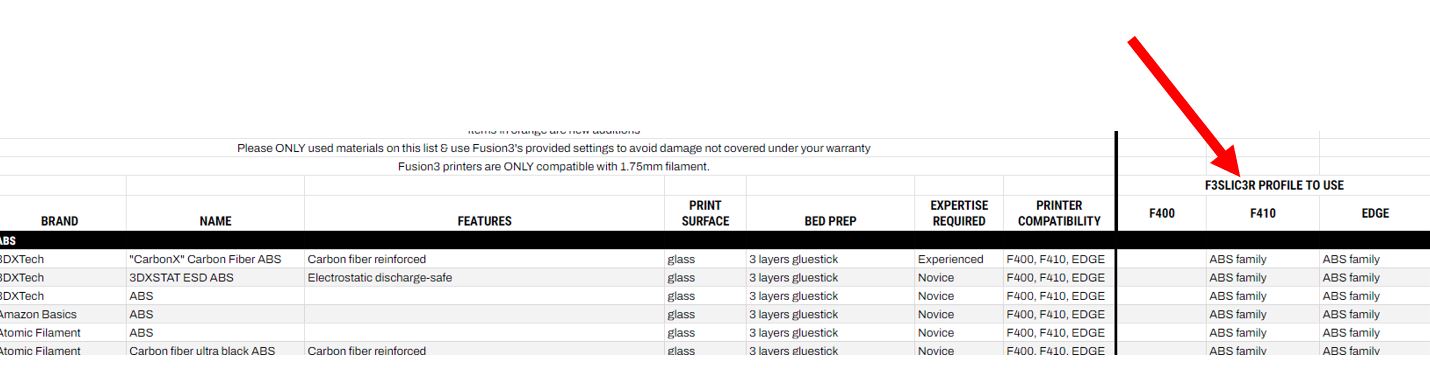

To support the release of our new slicer, f3slic3r, we’ve added some additional information to the Certified Materials List. On the right side are three new columns that tell you what profile to use in f3slic3r for a specific material.

Why do we need this? Unlike in REACTOR, where every material had its own profile, f3slic3r works differently. F3slic3r uses the concept of “family profiles”. That means there’s one ABS profile for every ABS on our list, for example. Family profiles make maintaining the software simpler and ensure higher accuracy of the profiles.

Some materials need different settings than the family profile has, and for those materials, we make a specific profile. You can see this in the nylons category where many of those materials need their own profile.

One final note: You’ll see the F400 profile column is blank. We don’t yet have f3slic3r profiles done for F400 machines, so for the time being continue to use your current slicer.

Glass-Filled Alloy910 (GF-A910)

New material from Xtellar (acquired Taulman). Variant of their highly successful Alloy910 nylon.

- Prints with our standard Alloy910 profiles on all platforms.

- Tighten extruder idler bar springs to ~9mm (0.36″). (Normal gap is 0.425″)

If you use this material extensively you may see higher wear rates on the extruder and print heads; keep an eye on things.

Carbon-Fiber Alloy910 (CF-A910)

New material from Xtellar (acquired Taulman). Variant of their highly successful Alloy910 nylon.

If you use this material extensively you may see higher wear rates on the extruder and print heads; keep an eye on things.

PCTPE

Taulman/Xtellar material. Used to be approved but fell off the list, so we’re re-adding it. High tensile strength semi-flexible material. May be suitable to replace high Shore hardness (>95A) TPU/TPE in some use cases. Compatible with all platforms.

“CarbonX” ASA+CF

3DXTech material – combines UV resistance, temperature resistance of ASA with carbon fiber for additional stiffness.

- Prints with our standard ASA profiles on all platforms.

3DXTech is known for very high fill % in their materials. If you experience jams or feed issues on 0.4 nozzles, consider going up to 0.6mm.

“Silk” PLA Family Profile (f3slic3r only)

Silk PLA is a relatively new take on PLA. It has some interesting surface finish properties and is becoming increasingly popular among hobbyists. Created by adding additives to PLA; side effects are weird flow behavior and requiring different temps. We’ve created a generic family profile for these materials. We are not explicitly certifying any silk PLAs at this time so we cannot guarantee you won’t experience print issues with silk PLA.