How To Properly Store Your 3D Printing Filament

3D printing is a garbage in, garbage out process. One of the key factors in ensuring you get great results is keeping your filament dust-free and dry.

There are 2 major areas we’re concerned with:

- Moisture

- Dust

PLASTICS JUST WANT TO ABSORB MOISTURE

All thermoplastics absorb moisture.

When that plastic is melted, that moisture boils off and can cause all sorts of issues during printing. Depending on the material and the amount of moisture you will see surface imperfections such as tiny holes and uneven layers.

Different plastics absorb different amounts of moisture.

- Compared to other plastics, PLA and ABS absorb less moisture as a percentage of weight.

- Other plastics such as PETG, Nylon, Nylon Blends, Polycarbonate, and Acrylic absorb significantly more and must be treated with more care.

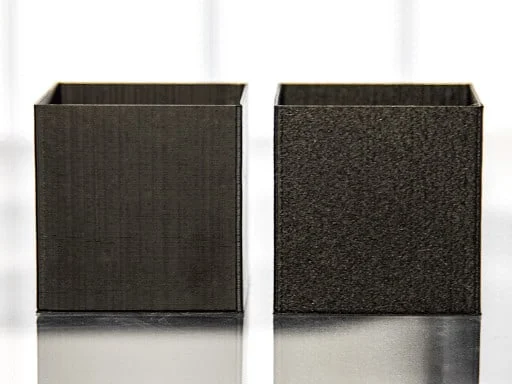

Clean & Dry Filament (left)

vs. Improperly Stored Filament (right)

(Credit: Matterhackers.com)

TO GUARD AGAINST DUST ON YOUR FILAMENT

- As with moisture, the best prevention for dust on your filament is to properly store your materials (sealed bag and sealed tub).

- However, if your material is prone to collecting dust, you can still get great printing results by creating a filament wiper that sits right before the material enters the extruder.

The Fusion3 F410 has its own filament wipe feature. For older 3D printers, its simple to make your own filament wiper. For example:

- You can take a piece of coffee filter and a closepin.

- Just fold the filter over on itself and clamp it in place with a clothespin. The tension of the clothespin should be enough to hold it in place, while allowing the material to enter the extruder without any resistance.