Using the E3D silicone printhead ‘sock’

Since January 2017, all Fusion3 F400 3D Printers ship with the E3D silicone print head sock which provide a number of safety and performance benefits.

For background, most print heads and nozzles are exposed to the air. Over time, the print heads will not only rust, but material can stick to the print head’s heater block and/or nozzle assembly. Removing the material is very difficult and in some instances, can ruin your print head, requiring replacement of the part.

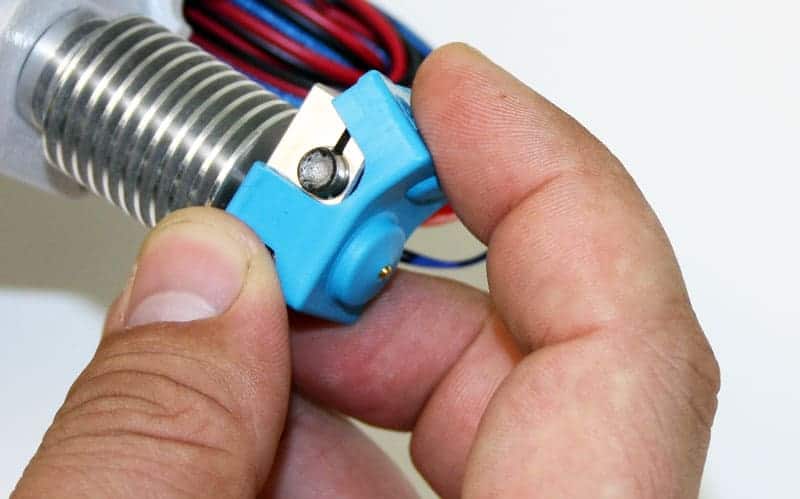

E3D, Fusion3 supplier of print head and nozzles, now ships their v6 and Volcano print heads with a cover (‘sock’) made of industrial grade silicone. The sock is not a shipping cover, please leave them on as they provide a number of benefits for our users:

KEEPS PRINT HEAD CLEAN OF DEBRIS: Since silcone is non-stick, your print head will remain clean and prevent filament from sticking to the header block or nozzle.

HEAT INSULATOR: The sock also acts as an insulator for the print head. It will reduce heat up time and help maintain a constant temperature during printing.

MINIMIZING CRITICAL FAILURES: We tend to see 2 major failures for prints that can affect the print head. First, if filament starts to jam up outside of the print head, a ‘birdsnest’ can be created which is difficult or impssible to remove. Also, if the part were to detach from the print bed during mid-print, it could get stuck to the print head and be dragged around causing damage to the printer. In each case, the silicone of the sock can prevent material from sticking and reduce or eliminate these issues.

If you don’t already have the print head socks or require a replacement set, they are available for purchase from the Fusion3 Replacement Parts store.

E3D Silicone Print Head ‘Sock’