Fusion3’s 3D Printing Filament Testing & Certification Process

We at Fusion3 love that there’s a multitude of 3D printing filament manufacturers bringing different types of material to the market. It’s this variety that is the basis for our ‘Open Material Philosophy’ which ensures that our customers always have a wide selection of materials available for you.

In 2015, Fusion3 was the first 3D printer manufacturer to create and implement, a rigorous filament testing and certification program.

The goals of Fusion3’s Material Certification program are to:

- Variety:

Make the widest variety of 3D printing materials available to our customers, with an emphasis on engineering-grade materials for use in commercial environments. - Quality:

Ensure that the materials certified are of high quality. - Provide Optimized Settings:

Ensure the customer will get the best results from the materials ‘out of the box’, by providing optimized settings for each material created by Fusion3 expert staff. If the customer utilizes these settings, and if they have an issue during printing, either we can eliminate many variables due to the material settings or have a baseline for our support teams to help diagnose issues from.

IMPACT OF USING POOR QUALITY 3D PRINTING FILAMENT

In our many years of 3D printing industry industry experience, we’ve found that poor quality 3D printing filament can cause a multitude of issues.

What types of quality issues arise and impacts they cause?

- Poorly sealed packaging.

Plastics will absorb humidity from the air and likely a package will sit for a month or more before it even arrives to you. A poorly sealed package will leave your filament with too much humidity which can lead to stringing and other print defects. - Poor quality base plastics or foreign materials within.

Some manufacturers will cut corners with shoddy base materials or allow foreign materials ranging from dirt to metal objects to mix with the plastic. This will also impact your print quality and could damage your 3D printer either directly or lead to print jams. - Inconsistent Extrusion.

It is important that the extrusion width of the material is consistent throughout the entire roll and does not exceed certain parameters. Too wide and can cause a jam. Too much variability and it will be impossible for a performance 3D printer, like Fusion3’s, to operate at speed and precision, if it cannot have a consistent amount of material fed into the extruder during a print.

In all, these issues can cause print head jams, part warping, and print quality issues.

Poor quality filament has a significant negative impact on the customer’s experience with our 3D printers and increased costs to provide customer support.

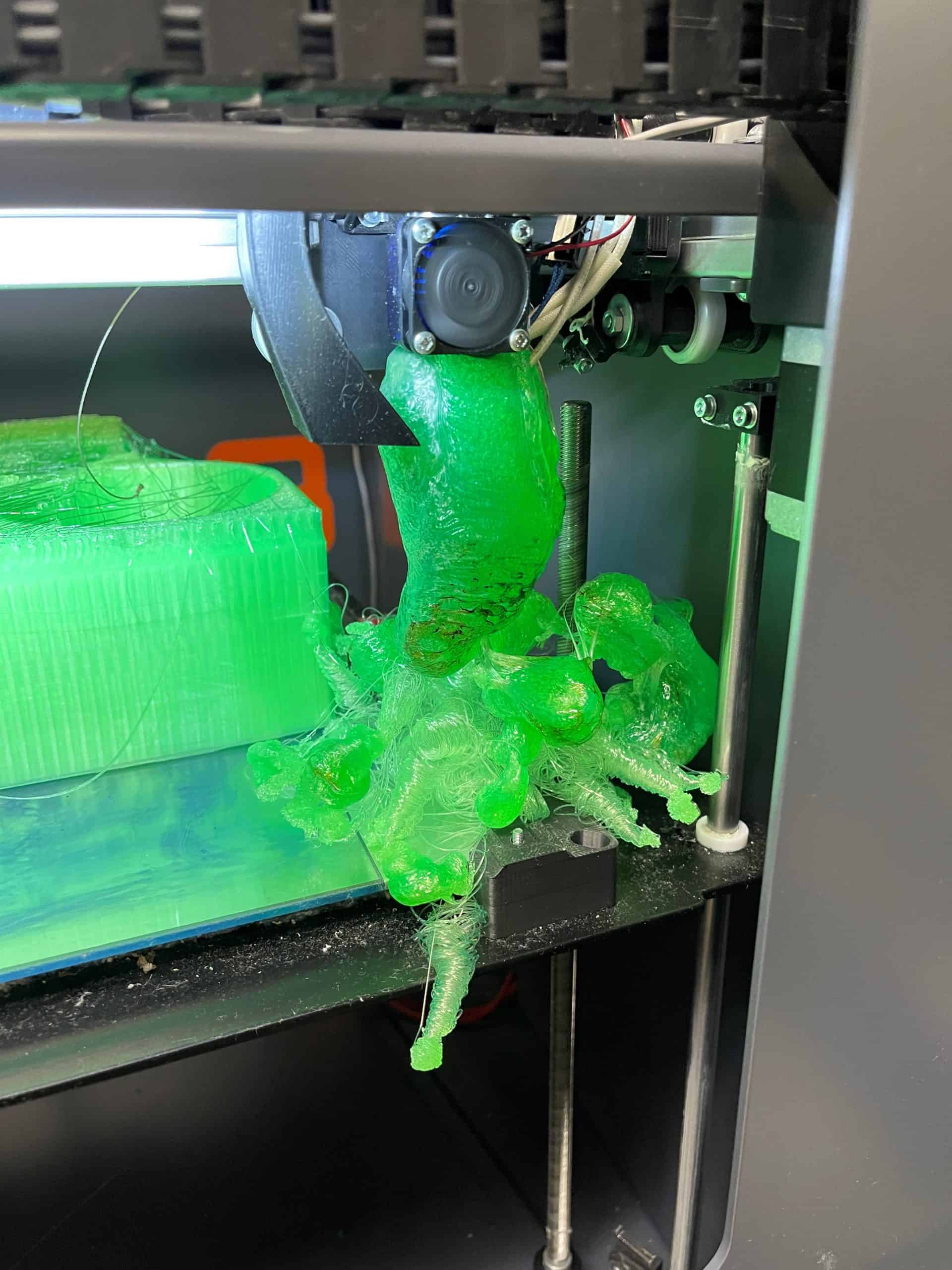

Print Damage Caused To A Customer’s 3D Printer Due to Poor Quality And Mis-Labeled Formulation

FUSION3’S TESTING & CERTIFICATION PROCESS

Since our founding in 2013, we have always provided optimized settings for our 3D printers and in 2015 established our program to test materials and publish our ‘Certified Materials List’.

What does the Fusion3 Material Testing & Certification Process Entail?

- Packaging:

We inspect the manufacturers packaging for airtightness. We also inspect the quality of the winding of the material on the spools to ensure that the customer would not experience tangling. Lastly, with the advent of recycled spools, we check for the type of spool material. Unsealed cardboard spools, while great for the environment, risk leaving a large amount of contamination on the filament itself in the form of paper fibers. - Extrusion Width:

We randomly test multiple rolls of the filament using high-precision equipment to ensure consistent extrusion width. - Contamination:

We visually inspect and with microscopes the content of the material for any possible contamination. - Print Quality:

We run a number of tests on the printer to gauge material flow and initial print results.

Should a filament pass these four (4) steps, we then do a number of different 3D printing tests and tune a series of material profiles for our various 3D printers.